High-flexible cables are now used more and more widely.

It is the occurrence of cable fire accidents in recent years that reminds people to pay special attention when using such cables.

So, what are the quality reasons for fire accidents caused by high-flex cables? Let's take a look at it!

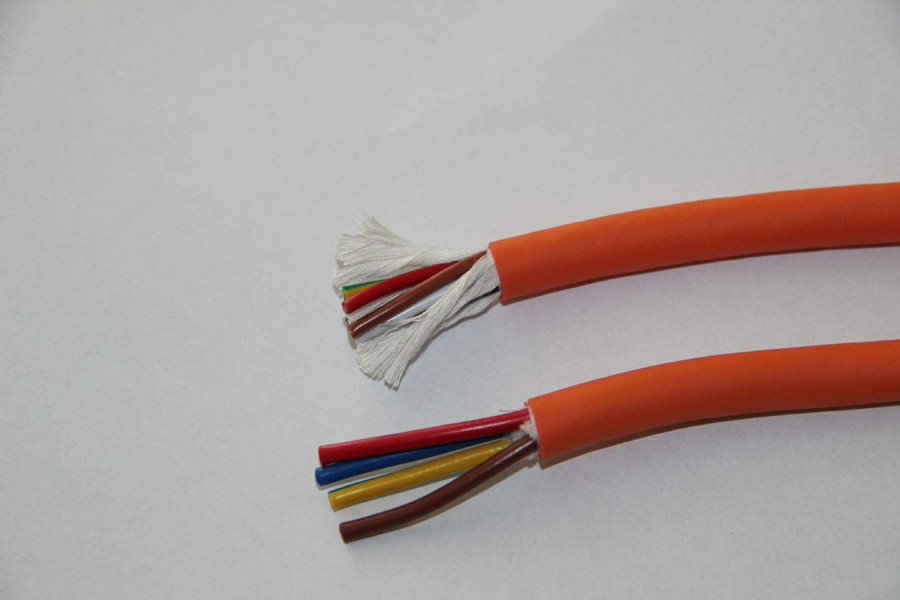

1 The nominal cross-section of the conductor of the cable core wire does not meet the requirements.

Generally, the nominal interface is larger than the actual cable produced, and the cable with a nominal value biased to the standard will have a larger cell current density.

During its operation, the cable is prone to fire due to the inability to generate heat normally. accident.

2 Producing cable is not strictly in accordance with the standard.

Even some merchants use inferior products to make them indiscriminate, resulting in the final production of the cable because the quality is not related to the fire during use.

3 The material of the cable is not pure or unqualified.

The core wire of the cable is generally made of some conductive materials of copper or aluminum, and many merchants often use materials that are not qualified or have insufficient purity in the production process, which causes them to be reduced because they contain more impurities.

Therefore, the material used as the core wire must be some high-quality electrolyte materials, generally copper and aluminum.

If you have any interest in our cable products, you can email us at info@zmscable.com or contact us via the "Contact Us" section of the website.